We recently purchased around 100 of these parts storage bins to start our small parts store. They cost $1.96/pc…however, the individual divders cost between $0.80 – $1.00/pc online (usually in packs of 24). Each unit has 7 divider slots, but typically you would only use 2-4 dividers per bin.

It would cost us between $160 – $400 additional dollars to purchase enough dividers for these 100 bins. And that is for just over one shelf worth of storage bins…we have 26 shelves of potential storage bins…that’s a lot of money!

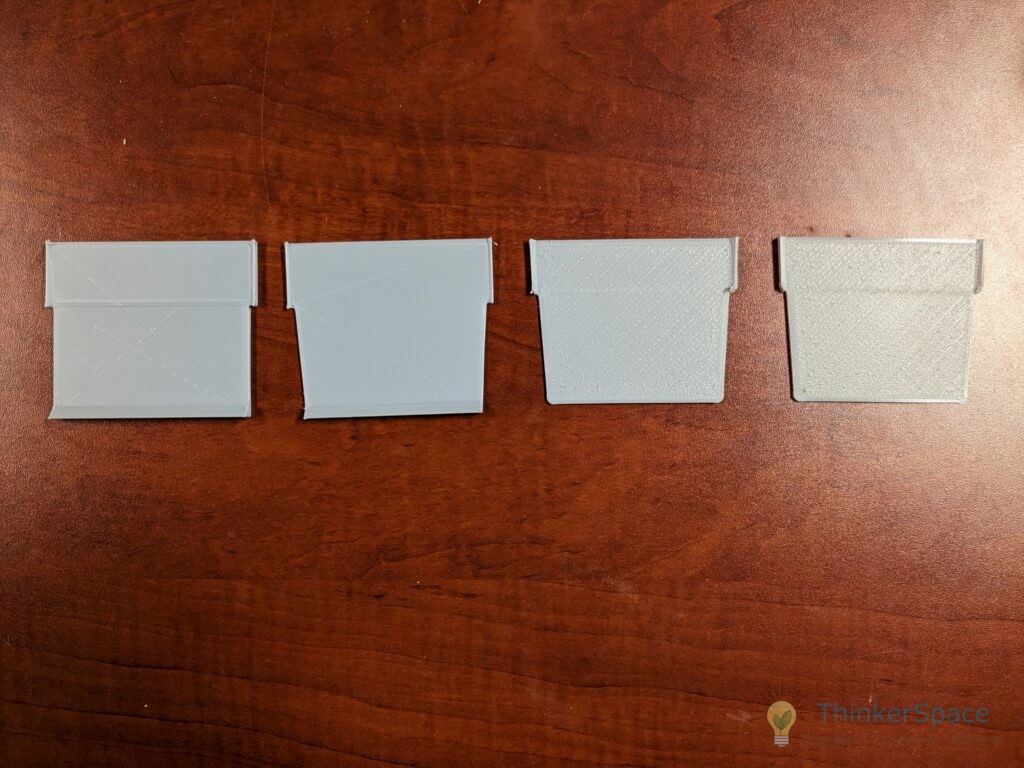

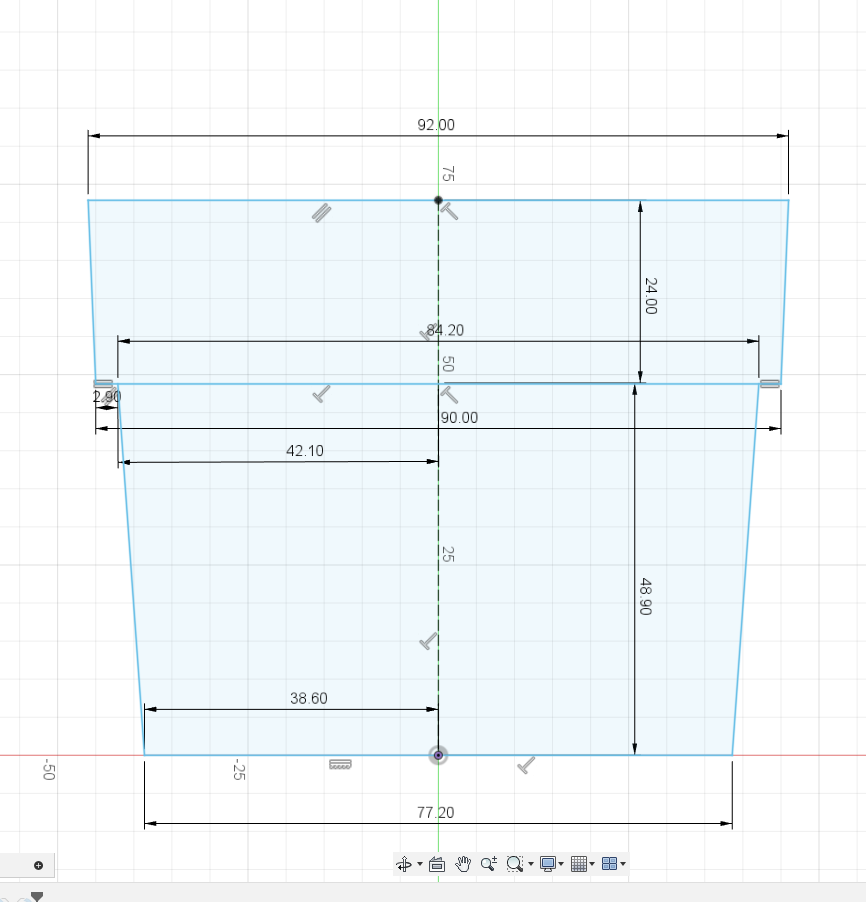

By taking some quick measurements and a rough sketch in Fusion 360, I experimented with a few iterations. The first one was made with the rough dimensions, has “wings” on the top edges to hold them in place securely, and given a curved “foot”. The thinking on the curved foot was that it would help when you scoop parts out of the bin.

The second iteration also had the curved foot but has a taper to accomodate the sloped sides of the bin. This was a little tricky as there wasn’t a way to fit the calipers inside the bin for a proper measurement. So I measured the outside and subtracted the thickness of the walls x 2 and a small tolerance.

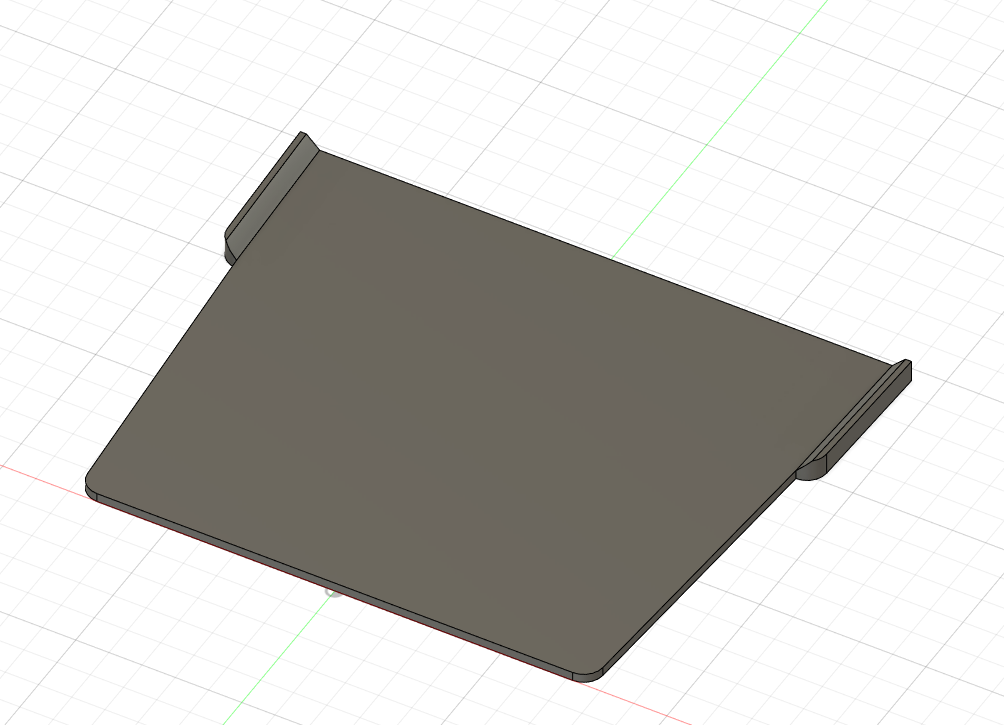

The third iteration has the correct slopes and I added fillets around the edges for a smooth fit. I also removed the curved foot to reduce print time, and reduced the thickness to a minimum. I hadn’t fully thought through the foot idea….I realized, not only would it greatly increase print time, but it also was in the way of the grooves at the bottom of the bin where it slots into place.

There are ways to fix the design, but I was looking for something I could print quickly and in mass. Adding a groove into the divider would have added additional complexity to the print, and require additional processesing per piece, raising the overall cost.

I further fine tuned the tolerances, decreased the infill to reduce weight and print time while still having a sturdy divider, the final iteration, is only 8.5g/pc

Current price breakdown as of June 2023:

1kg of grey PLA 1.75mm filament costs me around $17.50 shipped from MatterHackers (this is the volume price when ordering 12 or more reels).

At 8.5g/pc I can print pprox 117/pc per 1kg reel of filament or approx $0.15/pc

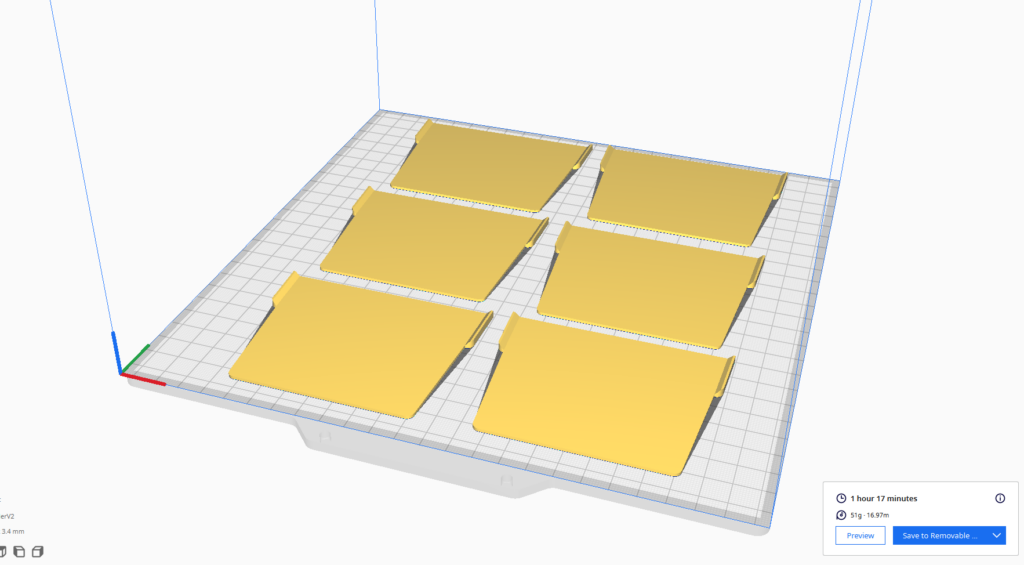

I print 6 at a time in around 1hr and 25 minutes (on the AnyCubic Vyper, about twice that on the MegaX), which consumes around 100w/hr and costs around $0.01 per set of 6.

There is minimal clean-up, I used a deburring tool to clean up the stringing around the wings. If I were to sell these I would include a processing fee.

Other costs to consider are operating cost to own and maintain the 3D printers, rental fees, insurance, and your design time (I typically charge $50/hr for design services), this was a simple part, took only minutes to create, and iterate, but other parts may take hours!

It is satisfying to create your own parts, but make sure to consider all your expenses and to compensate yourself appropriately if you are doing this as a business!

Leave a Reply